Market Potential of RTE Gravy

The Indian market for ready-to-eat (RTE) is expanding and turning itself inside out to keep in step with an expanding set of consumers, who are not only eating healthy but are also struggling with busy lifestyles. Busy lifestyles have prompted time crunched consumers in urban India to look to easy solutions such as ready gravy mixes with detailed instructions on how to cook them on the product packaging.

RTE gravy pouches can be:

01.Microwavable

02. Re-sealable pour spout

03. Retort

Making gravy by hand might seem easy enough, but in the industrial era, people have started shifting towards RTE gravy to save time. Nowadays, one can go into any store and find a plethora of little pouches packed with powder. Add water, heat, stir, and it’s ready. Indeed, the texture, smell, and taste of these mixes are certainly gravy-like.

But home-cooking is to industrial food processing what walking is to flying an airplane. The gravy mix isn’t just huge vats of drippings mixed with flour and water. More than a century’s worth of food engineering have gone into making a powder you mix with water and microwave in three minutes to manufacture a smooth gravy.

“Modified starches, gelatin and gums such as carragheenin extract have been some of the ingredients used as thickening agents in the preparation of RTE gravy mixes.”

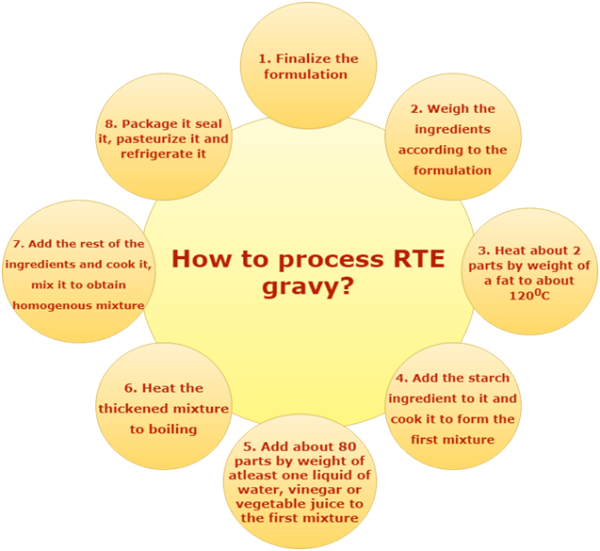

How to make RTE gravy?

Popular gravies at retail store

Some of the popular gravies you can find at the grocery store’s shelves are:

- Kohlapuri Gravy

- Manchurian Gravy Mix

- Chinese Chilly Gravy Mix

- Biryani Gravy

- Bhuna Masala Gravy

- Chicken Gravy

- Mutton Gravy