Instant Cup Noodles Manufacturing Guidelines

Instant Cup Noodle is a pre-cooked and dried processed food from flour that is dipped in seasonings and can be eaten straight from the pack by just adding heated water.

Huge scope in Instant Cup Noodles Market

01. Longer Shelf life of dried noodles

02. Rising demand of convenient and healthy food.

03. Lack of variants in Cup Noodles category

Why Instant Noodles?

- With increasing youth population, increasing disposable income, higher brand consciousness, and changing consumer preferences, Instant Cup Noodles make for a convenient on-the-go meal.

- Currently, the market does not provide many varieties of healthy instant cup noodles.e.g. flavours like masala, manchow, chicken and other non-veg only are available. This leaves an opportunity to develop healthy cup noodles with innovative taste variants.

- Being a dried product, it has a longer shelf life which saves the manufacturer from hassles of early spoilage as in case of perishable food items.

- In addition, same unit can be used for manufacturing of other food products like macaroni, spaghetti, vermicelli, chicken noodles, pasta.

- The Indian Instant Noodles market was valued at USD 1438.04 million in 2017 and is expected to register a CAGR of 5.6% during next 5 years.

- Cup/Bowl noodles are estimated to register highest growth rate of 5.8% in these years.

Manufacturing Process

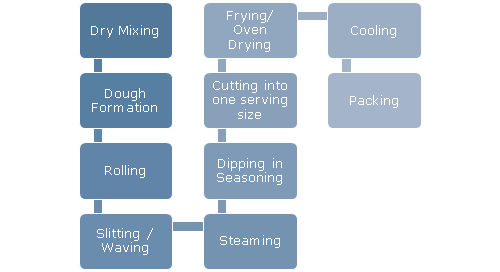

Manufacturing of Instant Cup Noodles can be either semi-automatic at small scale or fully automatic at large scale. The basic process for both cases is given in the flowchart below.

- Raw materials are mixed in the mixer and dough is formed which is allowed to rest.

- Dough is then sheeted and by compounding the sheets, a specified thickness of sheet is acquired gradually.

- Sheets are then slit into noodle strands followed by steaming.

- For Cup noodles, steamed noodles are dipped into seasoning tank whereas for packet noodles, this step is omitted.

- For instant noodles preparation, strands are dehydrated either by drying in oven or frying. Thus, either fried or non fried noodles can be made.

- This is followed by cooling and packaging in cups which are then sealed.

It is estimated that cup/bowl noodles will register highest growth rate of 5.8% in coming years.

Nutritional content of noodles can be improved by incorporating different fortified flours in the recipe along with wheat flour such as soya, buckwheat, oats, barley, and legumes flour, or by fortifying the seasoning. Various seasonings can be used to provide different taste variants as per the consumer’s requirement.