Flavored Papad Processing

“From the Sindhi plate to Rajasthani thali and the MalayaliSadhya, no Indian meal is complete without papad – the most visible ingredient in cuisines of all states and communities”

- Be it young or old, rich or poor, people across all sections relish papad, or papadum for many.

- These crispy thin crackers are also eaten as snacks or appetizers.

- These come in different sizes and textures such as mini papad, big papads, roasted papad, khakra and many more.

- Papad can be cooked by deep-frying, roasting over an open flame, toasting or microwaving.

Why Papad Processing?

- Wide targeted market – all age groups + rural and urban market

- Potential for exports

- Low-cost venture

- Possibility of a wide variety of flavored papads

- Employment opportunity for rural women

Papad Market in India

- There are a couple of national brands available but the market is predominantly controlled by local brands.

- Various varieties and flavors of papad are available which are named either on the base flour or the spices used like Nachni/Ragi , Garlic Papad, Bajra Na Papad, Kali MirchPapad, Urad Papad and many more.

MARKET POTENTIAL

- Low-Cost Venture

- Potential for exports

- Wide variety of flavored papads

- Easy preparation

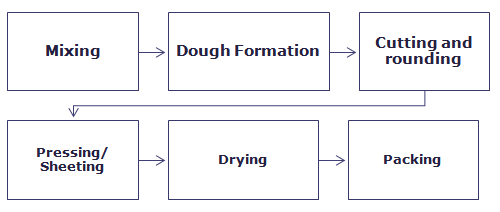

Papad Manufacturing Process

A papad can be prepared using a huge variety of natural ingredients such as lentils, chickpea, black gram, tapioca and much more along with a plethora of authentic Indian spices.

- The flour, spices, and oil are mixed with water to form a dough.

- The dough is allowed to rest for 30 minutes.

- Dough is cut into small balls and rounded.

- The rounded balls are either sheeted or pressed into circular discs of desired thickness.

- These are then dried to moisture content of 12%.

- Finally, the dried papads are packed.

Did you know?

“ShriMahilaGrihaUdyogLijjatPapad, the company behind very famous Lizzatpapad, started with a loan of Rs 80 and now has an annual turnover of Rs650 crore.”