Egg Powder Processing

“India is the third largest producer of eggs in the world. However, India is still a small player in the global egg powder industry, currently.”

Why Egg Powder Processing?

- Longer shelf life – Unlike fresh eggs which get spoiled in a few days, egg powder can last for over two years.

- Ease in shipping and transportation

- Changing dietary habits from carbohydrate-based food to protein-rich food.

- Increasing demand with flourishing bakery industry and food industry altogether.

- India’s cost of production of eggs is much lower than all other major producers.

Market Drivers

- High shelf life of egg powder

- Convenience and Nutrition

- Strong performance of foodservice industry

Egg Powder Exports

- Indian egg powder industry relies majorly on exports, with Germany and Japan being the largest importers.

- In 2017-18, India exported 4253.21 MT of dried egg yolk valued at Rs. 12,791.09 lakhs.

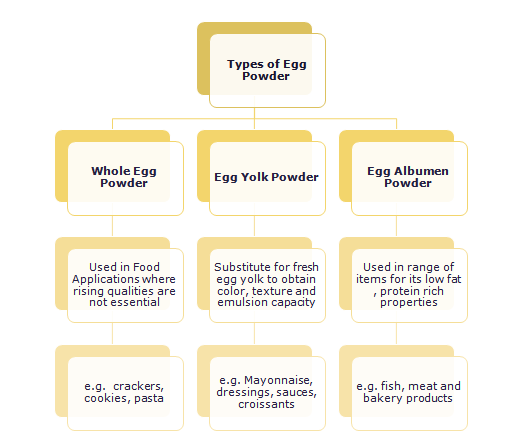

Egg Powders & Application

Manufacturing Process

- Eggs are broken and the outer shell is removed.

- Egg yolk and albumen are separated. This step is omitted in case of whole egg powder.

- The mixture or each component is filtered and stored in storage tanks at 4 Degree C.

- It is pasteurized in the tubular heater at about 65 Degree C for 8-10 minutes.

- It is dried in a spray drier which yields egg powder.

- Finally, the powder is packed as per the end use.

Did you know?

“The nutritional value of eggs does not depend on the color of their shells. So, brown eggs that are costlier than white eggs are not necessarily more nutritive than the latter.”