Disposal of Waste Water in Food Industry

At present, it may be admitted that water sources are the main concern in several economic areas. For this reason at least, innovative and advanced water reuse systems are becoming more interesting and promising technologies. However, the final goal can be obtained by means of different strategies, depending on merely

- volumes of wastewaters generated,

- chemical features of pollutants,

- physical–chemical parameters (biological oxygen demand, solid or liquid pollutants, etc.) and

- Variability of these characteristics, week after week.

Prior to consideration of new treatment systems or expansion of existing treatment works, measures sto reduce the volume and strength of the plant effluent should be taken:

- Segregation of wastewater and separately discharge or reuse.

- Recirculation and extensive reuse of water

- Implementation of process modifications and procedural changes to minimize wastewater generation

After all practical initial-step measures have been taken; the plant effluent should be re measured and reanalyzed. These data can then be used for:

- design purposes if new treatment facilities are contemplated,

- revising wastewater load and associated treatment efficiency expectations, if an existing treatment system is being utilized, or

- Reaching an agreement on or estimating service charges associated with discharge to a public sewerage system.

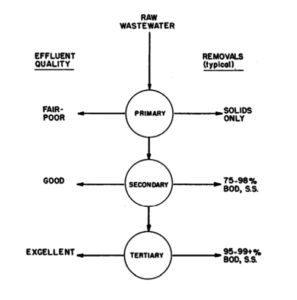

Wastewater treatment processes are grouped into 3 categories:

- Primary Treatment- It is designed to effect solids liquid separation. Biochemical oxygen demand (BOD) associated with the removed solids is also removed while the BOD in the soluble phase, the bulk of the BOD load from fruit and vegetable processing, is not reduced. Equipment used for primary treatment includes screens, clarifiers, and air flotation devices.

- Secondary Treatment- Most BOD associated with food processing wastewater is removed in secondary treatment. The biological processes most commonly used include activated sludge, aerated ponds, and trickling filters. The most commonly used physical-chemical process is coagulation-flocculation in conjunction with sedimentation or air flotation.

- Tertiary Treatment- Wastewaters reclaimed by tertiary treatment may be suitable for reuse in many food processing plant unit operations, particularly ancillary operations such as cooling. While tertiary systems are used principally to remove nutrients, refractory organics and heavy metals from secondary effluents, these systems also reduce effluent BOD and suspended solids concentrations to extremely low levels.

The most commonly used tertiary processes include:

- Chemical (lime, alum, or ferric) coagulation and sedimentation;

- Fine or mixed media filtration; and

- Disinfection employing chlorine.

Special tertiary processes occasionally applicable include carbon adsorption, ultra-filtration, and reverse osmosis.