Dehydrated Fruit & Vegetable Processing

Why are Fruits and Vegetables dehydrated?

- Preservation – Shelf life of dried fruits and vegetables is more than 1 year depending on their type and storage temperature.

- Lowers the cost of packaging, storing, transportation.

- For direct use in the manufacturing of processed food like instant vegetable noodles, soups, snacks and fast food.

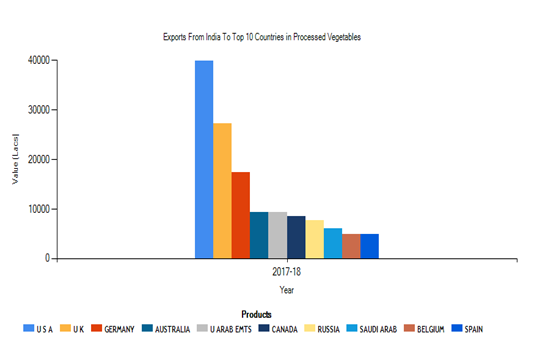

Indian exports

India is a prominent exporter of dried and preserved vegetables to the world. The country exported 88535.56 MT of dried and preserved vegetables to the world for the worth of Rs. 944.65 crores/ 146.54 USD Millions during the year 2017-18.

Dehydrated Fruits & Vegetables

- Round the year availability

- Huge Potential in exports

- Increasing demand with increasing food processing companies

Major dried fruits and vegetables in demand

1. Vegetables: Onion, Ginger, Garlic, Okra, Potatoes, Cabbage, Peas, Carrot, Mushrooms, Beans, Green pepper

2. Fruits: Pineapple, Mango, Peach, Berries, Prunes, Figs, Apricots

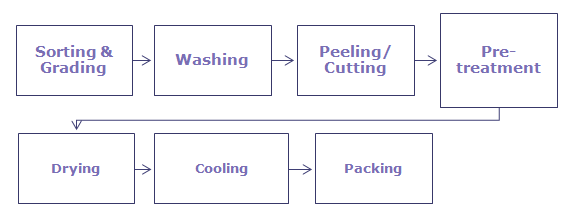

Manufacturing Process

- Sorting and Grading are done to remove the blemished ones and grade according to size and color.

- It is followed by washing, peeling or cutting as desired.

- Pre-treatment – Vegetables are blanched whereas fruits are sulphur-treated to inactivate enzymes (this halts browning).

- Drying is done to reduce the moisture content up to the desired level. There are various different kinds of dryers with different properties to choose from.

- Dried fruits and vegetables are allowed to cool down for some time so as to prevent any condensation/sweating in the package.

- Finally, packing is done.

Did you know?

“India is the second largest producer of fruits and vegetables in the world. However, only 2% of fruits and vegetables produced are processed, compared to 65% in the US.”

Packaging

The packaging of dehydrated fruits and vegetables must

- Protect the product against moisture, light, air, dust, microflora, foreign odor, insects, and rodents.

- Provide strength and stability to maintain original product size, shape, and appearance throughout storage, handling, and marketing.

- Consist of materials that are approved for contact with food.

- Be cost effective.

Majorly used Package types include cans, plastic bags, drums, bins, and cartons, and depend on the end-use of the product.