5 Checklist to Evaluate Food Co-Packer for Extrusion Snacks

Co- Packer provides assurance to the quality standards for the products.

Food extrusion is a form of extrusion used in food processing. It is a process by which a set of mixed ingredients are forced through an opening in a perforated plate or die with a design specific to the food, and are then cut into a specific size by blades. The machine which forces the mix through the die is an extruder, and the mix is known as the extrudate.

The Basic checklists to evaluate Food co packers are:

- Seasoning

- Type of Extrusion

- Finished good specification

- Product Quality

- Volume of production

Seasoning

- Seasoning is a very important factor in extrusion industries, good quality and variety of seasonings are a major challenge to sustain in the industry. The factor to click the UMAMI is what is needed in extruded snacks.

- The right knowledge of production process is also important for the seasoning to create its magic.

- Its very important for the co-packer to be expert in the above labels to work in extrusion field.

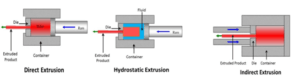

Type of Extrusion

- Extrusion is classified in general into four types. They are: Direct extrusion, indirect extrusion, impact extrusion and hydrostatic extrusion.

- In extrusion process, the billet is placed in a container, pushed through the die opening using a ram and dummy block.

Finished Good Specification

- The FG specification provided by the company end is the final and foremost issue to look on,be it size shape,texture,color etc.

- FG specifications varies within company to company end which helps them to sustain in the industry as their USP.

“Quality on specifications are treated as USP within different companies”

“Extrusion enables a mass production of food via a continuous,efficient system that ensures uniformity of the final product”.

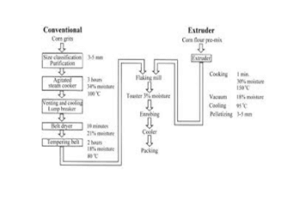

Process Flow chart in Extrusion snacks Industries :

Many food extrusion processes involve a high temperature over a short time. Important factors of the extrusion process are the composition of the extrudate, screw length and rotating speed, barrel temperature and moisture, die shape, and rotating speed of the blades. These are controlled based on the desired product to ensure uniformity of the output.Proper knowledge regarding the material is important factor for processing of quality products.

Product Quality

- According to the critical parameters that may partly affect the bulk density, expansion ratio, absorption, solubility, texture and nutrition of extruded snacks are: feed moisture, composition of raw food material, thermal energy input, and retention time. These are the parameters which may affect the quality of the product.

- Without the quality product, no organization can stand in the market as competition in this sector is very high.

Volume of Production

- Co packing industries need to have high ton production machineries which can produce huge volume at one use. As extruded products are highly viable to huge energy consumption ,hence its recommended to use high capacity machineries.

- Profit magin at both the ends sustain on the very factor of volume of production.